Image

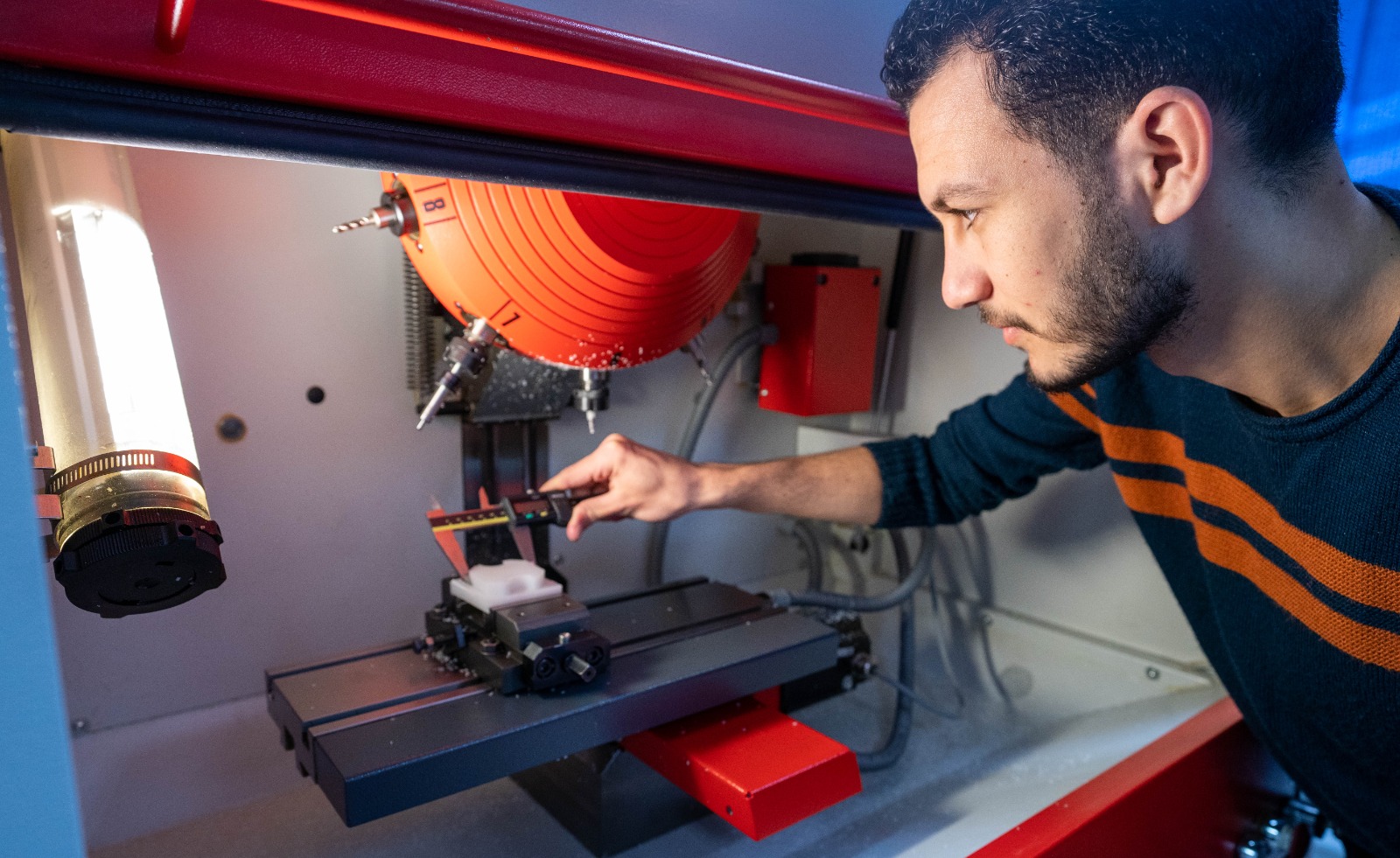

CNC Basics - FANUC Series 21 Lathe and Mill (CNC 412)

Course Details

|

|

4 days/32 hours |

|---|---|

|

|

Basic engineering understanding |

|

|

CNC |

|

|

English |

CNC machines are one of the most important equipment used in industry to produce parts. This workshop will provide the necessary know-how based on hands-on training on real industrial equipment upon the ISO G-Code language FANUC variant.

- Brief history about the ISO G-Code language: the beginning, the actual state, the industrial point.

- Principles of ISO G-Code programmation.

- Organization of a single instruction and the complete structure of a Block.

- Description of the words set: N, G, F, S, F, T, M.

- Syntax of the ISO G-Code words for Milling and Turning machines.

- Systems of Coordinates: Absolutes and Relatives, Cartesians or Polars.

- Machine coordinate system and user coordinate system.

- Set-up of the machine for the required job.

- Tool path: kind of paths and its control.

- Technological parameters.

- Structure of a NC program.

- Samples according to FAN UC Series 21.

- understands the basics on how to program a CNC Machine.

- understands how to manage the System of Coordinates.

- understands how to control the tools and the tool movement.

- knows the structure and the syntax of a single block of ISO G-Code FANUC Series 21.

- knows the set of Words for Lathe Machines and for Milling Machines equipped with a FANUC Series 21 Numerical Control.

- is able to read and write simple NC programs through the FANUC Series 21 Machine Interface.

- is able to open an NC program and modify some instructions or add new blocks/words.

- is able to define and put into the NC program the technological parameter.

- understands the differences between Machine Coordinate System and User Coordinate System.

- is able to simulate the tool path and understand it.